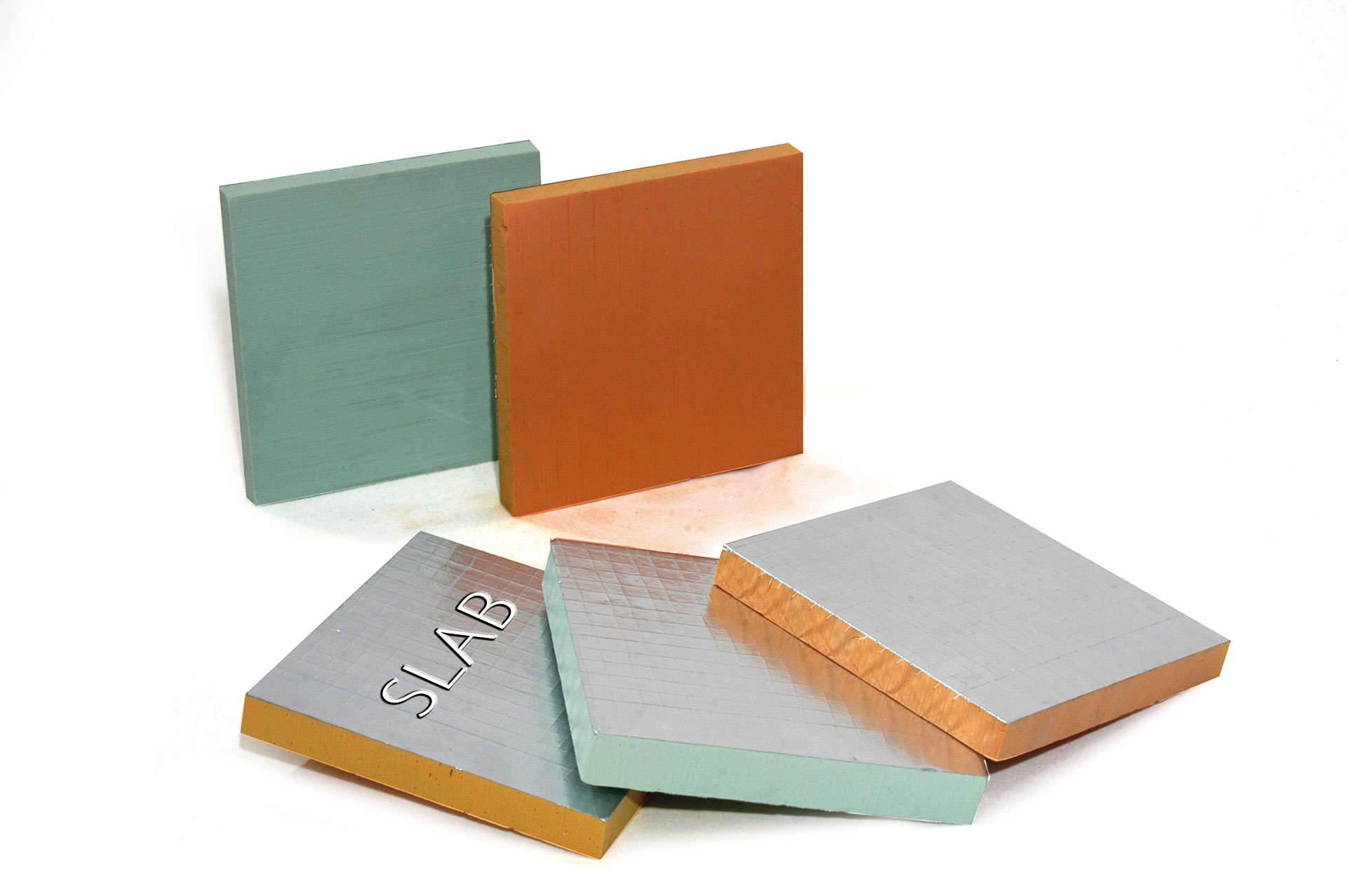

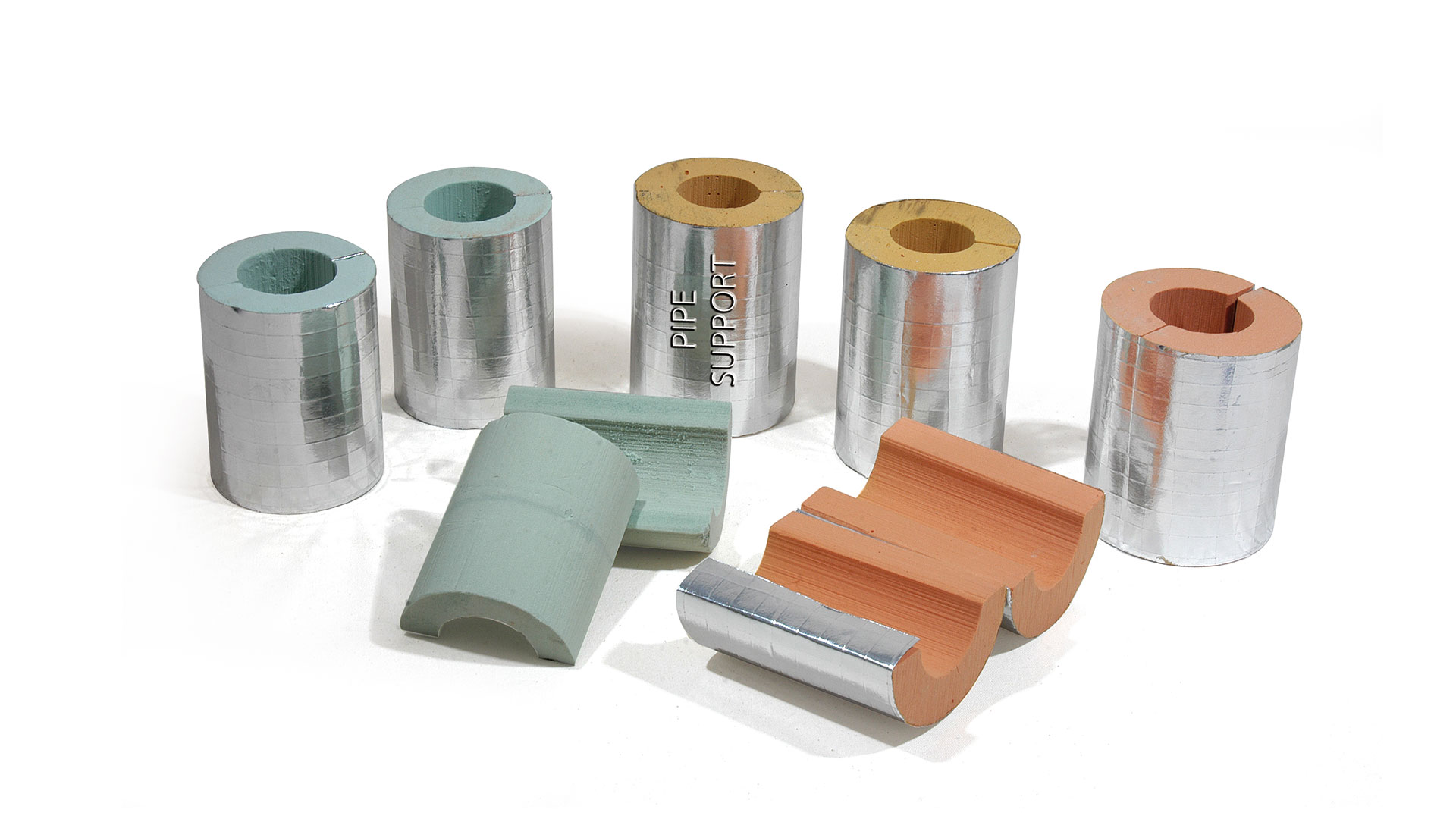

Closed Cell

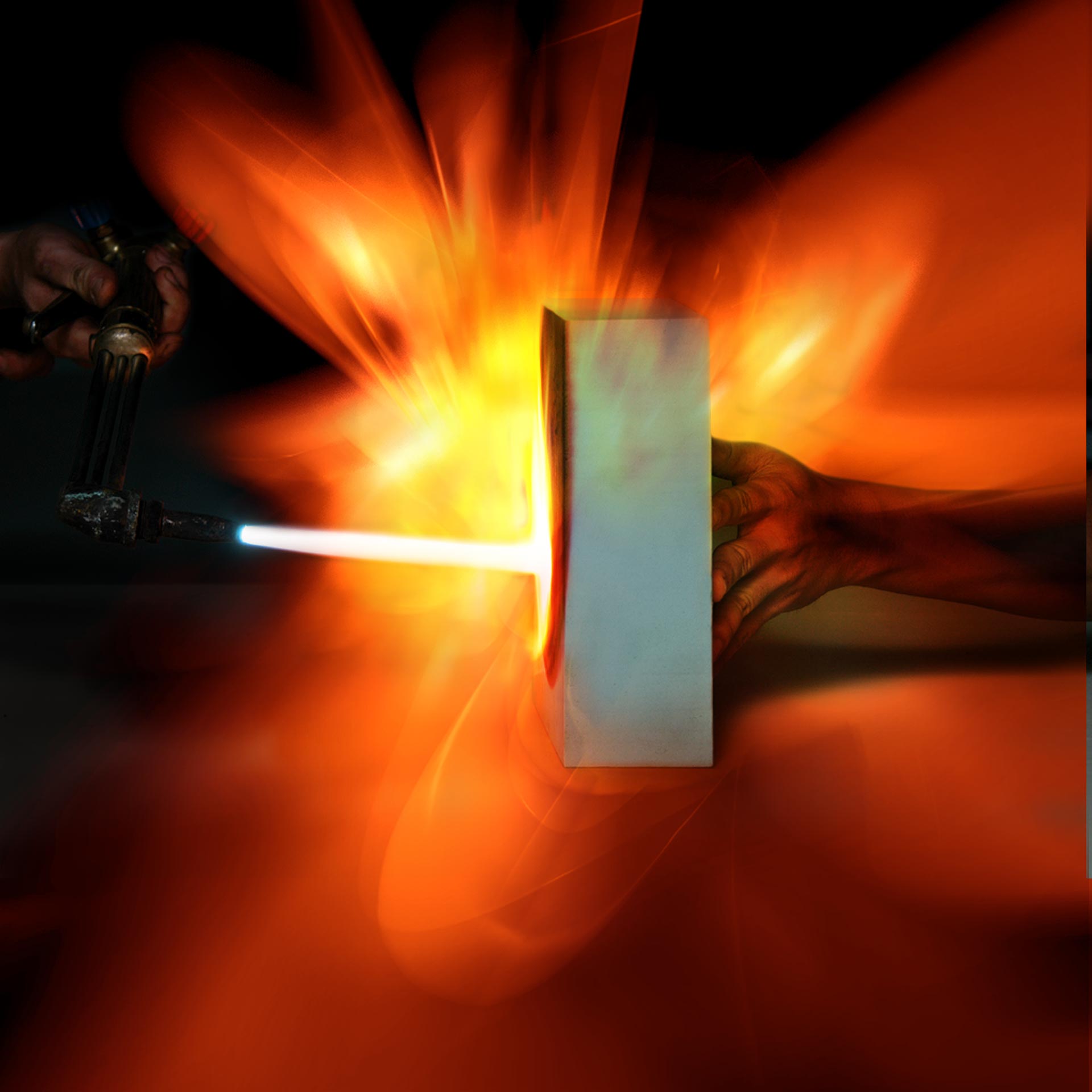

Formalphen is produced with a closed cell structure in excess of 90%. This feature assures a product with an exceptionally low thermal conductivity (k-value). Formalphen’s closed cell structure limits any direct moisture absorption (and subsequent insulation failure), should a cold system’s vapour seal be damaged. This type of failure is a major weakness of open cell and fibrous systems.